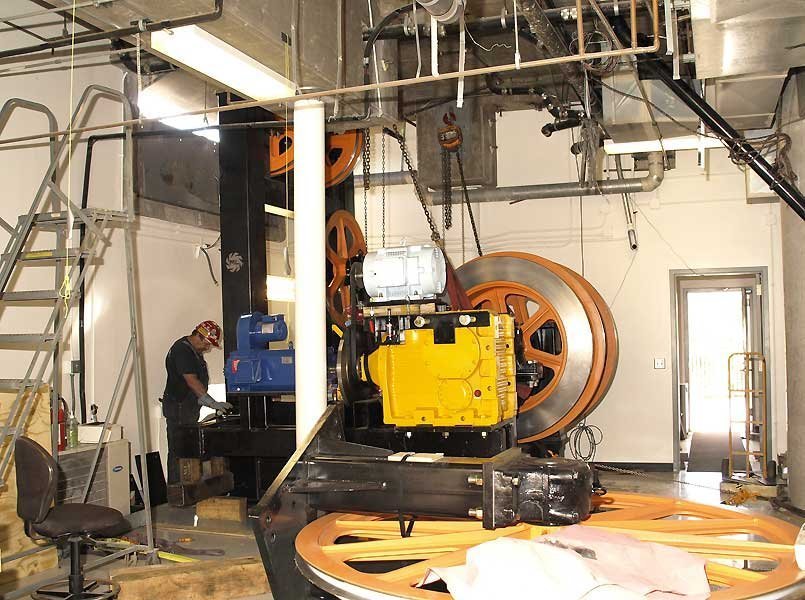

Drive assembly work, cable spool, 11/15/07

Work continues on assembling the modules of the Drive Assembly into one functioning unit. Not only are the modules being brought together, but the two electric motors and gearbox are being installed as well. In addition, the spool of cable that will bring the cars up and down the track will be brought up into the Machine Room via fork lift. At this point it is still a long way from “powering up” the new Drive.

Legal Notice

The name “Angels Flight” and the images of the Angels Flight® Railway and cars are copyrights and registered trademarks of the Angels Flight® Railway Company and are used with permission. The content of this website, www.picturetrail.com/afrp (this “Site”), including but not limited to the text and images displayed herein and their arrangement (collectively, the “Materials”), are copyrighted © by Leonard Auslender, whether or not they bear © notices and warnings. The Materials on this Site and any other World Wide Web site owned, operated, controlled or used by Leonard Auslender for the display of any of his images and/or text may not be copied, distributed, republished, uploaded, posted or transmitted in any way without express written permission detailing specific fees and conditions of use. No permission is granted to print, copy, reproduce, distribute, transmit, upload, download, store, display in public, alter or modify the Materials, hyperlink other websites to this Site, or to use Leonard Auslender’s or the Angels Flight® Railway Company’s photographs, text, trademarks, trade names or copyrighted materials for any reason. Mr. Auslender can be reached by clicking HERE.

The Source of Power

This motor — still dusty from its trip on the truck — along with the special gearbox, will be the source of power for the whole thing.

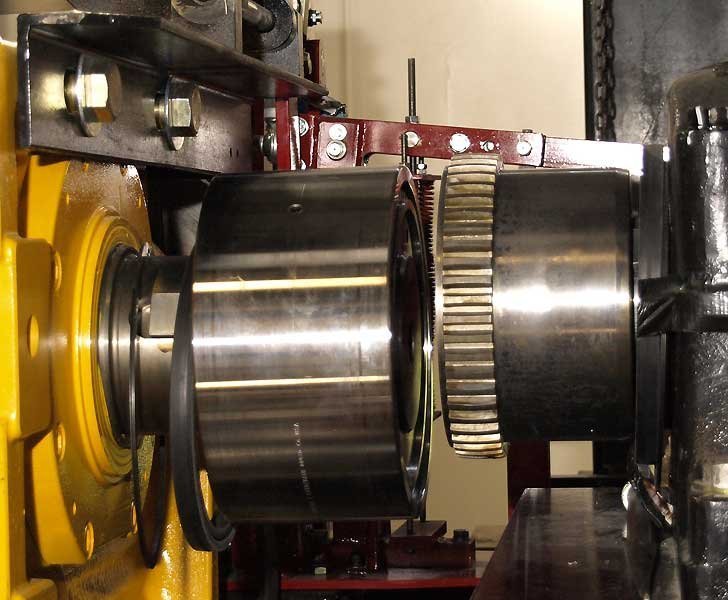

The Gearbox

All the parts must fit perfectly, and it’s not easy!

Tools of the Trade

Hand-operated winches, like this little “come along,” and chains are indispensable tools in getting things moved and placed.

Clowning Around

“Hey Leonard, it’s about time YOU got in one of these pictures!” That’s what they said anyway. So I consented to have my picture taken. What did they do? They focused on the guy popping up behind me like Kilroy!

Exact Fit

You see the slot on the left-hand frame. There’s another directly opposite. As they bolt these two pieces together — slowly, carefully — there’ll be a dowel that fits in the double slot, guaranteeing an exact fit.

Power Transfer

One of the many reasons for an exact fit everywhere is because the output shaft coupling from the Gearbox must connect precisely to the coupling on the Drive Shaft that turns the Bullwheels that move the Haul Cable and, thus, the two cars.

Getting Closer

Eventually, these two parts dovetailed perfectly.

Now for the Cable!

The spool of cable weighs over a ton. There’s a thousand feet of cable. You can roll it, but that’s about all. It will make the fork lift trip up to the Machine Room, just the way the rest of the equipment has.

600mm

It’s in situations like these, where I deploy my telephoto zoom, bringing a higher level of interest and drama to the proceedings. The 4/3rds sensor on the Olympus E series of cameras means lighter weight and portability, obviating the necessity for a tripod or monopod — thank goodness!

Destination Reached

The cable comes to rest on the Machine Room floor, where it will stay until near the end of the project, when 300 of the 1,000 feet will be used for each the Haul Cable and the Safety Cable that will connect the two cars.

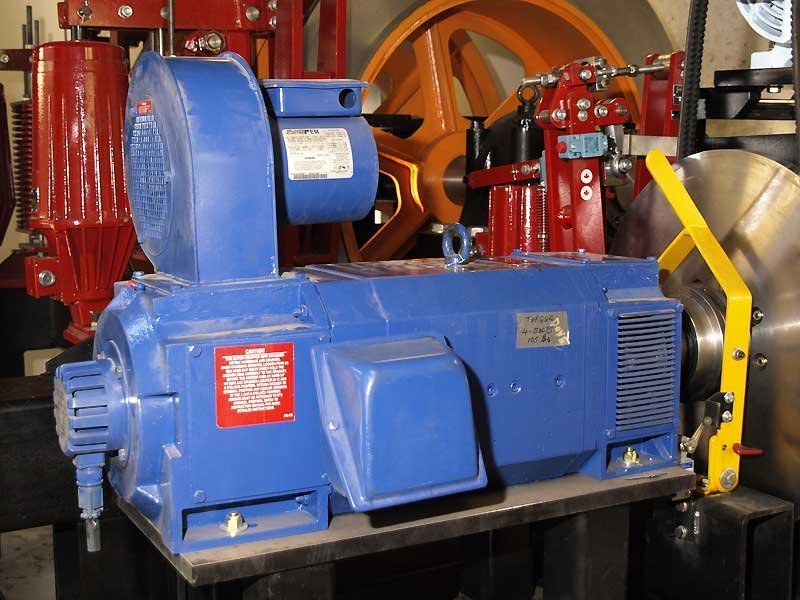

Evacuation Motor

This powder blue motor is on standby in case there is a malfunction with the regular Motor.

So Far, So Good

Coming Along Nicely

The Motor and Gearbox module is in place waiting for more tweaking. The last component of the Drive Assembly — the large Reversing Sheave — sits on the Machine Room floor on its side, waiting to be fit into the rest of the puzzle.